|

Paper

Paper consists of fine vegetable

fibres which are extracted from wood. These fibres

are made of cellulose. Both coniferous (softwood

trees) and deciduous (hardwood trees) can be used

to provide the untreated material which is called

wood pulp. Cellulose fibres can also be taken

from other plants like hemp, flax, cotton and

bamboo. However the most common material source

to make paper from is wood. Wood pulp has numerous

different chemicals added to it. This is done

so the wood pulp can achieve the required texture

and surface finish required to make paper.

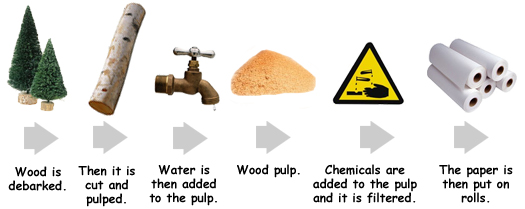

The stages involved in making paper

The paper making process

The paper making process has remained basically

the same for the last two thousand years. Tiny

chips of wood are cooked in water and chemicals

to make a mushy wood pulp. The pulp is then poured

through a filter or a fine mesh. As the water

drains away, the cellulose fibres (which are less

than 1mm in length) naturally join to form the

papers structure. The paper then moves through

a set of machine rollers which flattens the paper

and removes any left over water. Flattening the

paper makes the mesh of fibres stronger.

Paper comes in different sizes. ‘A’

sizes are the most common, standard sizes are

A4 and A3. Use the grid below to work out paper

sizes.

| Paper |

Size |

Note: |

| A6

|

105mm

x 148mm |

|

| A5 |

148mm

x 210mm |

(Twice

the size of A6) |

| A4 |

210mm

x 297mm |

(Twice

the size of A5) |

| A3 |

297mm

x 420mm |

(Twice

the size of A4) |

| A2 |

420mm

x 594mm |

(Twice

the size of A3) |

| A1

|

594mm

x 841mm |

(Twice

the size of A2) |

| A0 |

841mm

x 1189mm |

(Twice

the size of A1) |

Board

Board is a general term used to

describe a whole range of paper based material

such as cardboard, mounting board, corrugated

board, etc. Board is thicker, heavier and more

rigid than paper as it is made from several more

layers of pulp than paper is. Very thick board

is made by sticking sheets of paper or board together

in a process known as laminating.

Laminating paper-based board

with other materials creates boards with different

qualities. These are known as composite materials

e.g. – cereal packets, egg cartons, orange

juice cartons, etc. A good example is foil lined

board this has foil on one side of the board and

is used for fast food containers to keep moisture

an heat in. |